PVC copper wire for submerged pumps

Copper conductor, not tinned, insulated with modified PVC for high voltage, used for the construction of motors submerged in water or oil. The special nature of the insulation gives this conductor excellent resistance to ageing, high dielectric strength, good insulation, good loss factor, good thermal resistance, good resistance to chemical agents.

INSULATION

:- the thickness of the insulation wall depends on the diameter of the conductor

- special mixture of PVC; wall thicknesses: 0.35.0.8 mm

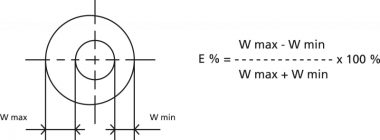

TOLERANCES

| EXTERNAL DIAMETER OF INSULATED WIRE | TOLERANCE ON THE EXTERNAL DIAMETER OF INSULATED WIRE | ECCENTRICITY | INTERNAL DIAMETER OF THE COPPER WIRE |

| ± 0.05 mm | ≤ 10% | 1% | |

| 2.21 – 3 mm | ± 0.07 mm | ≤ 12% | 1% |

| 3.01 – 6 mm | ± 0.10 mm | ≤ 15% | 1% |

| > 6 mm | ± 0.15 mm | ≤ 15% | 1% |

TESTS:

Every production lot is tested 100%:

a) Dimensional check of bare copper

b) Dimensional check of insulated copper

c) Eccentricity

d) Surface check

e) Check for flaws

f) Test voltage check (*)

ELECTRICAL DETAILS

| OPERATING VOLTAGE | 50HZ | 600-1000 V | |

|

TEST VOLTAGE AFTER 2X24H IN WATER AT 20°C |

15 MIN/50HZ | 2500 V | |

| OPERATING TEMPERATURE | 70°C | ||

| LOSS FACTOR TAN δ | SEC DIN53483 |

20°C/800 HZ 70°C/800 HZ |

6×10-2 8×10-2 |

| DIELECTRIC CONSTANT | SEC DIN53483 |

20°C/800 HZ 70°C/800 HZ |

3.5 7.5 |

| SPECIFIC INSULATION RESISTANCE | SEC VDE0472 SECTION 502 |

20°C/500 V DZ 70°C/500 V DZ |

1015 Ω cm 1015 Ω cm |

|

BREAKDOWN VOLTAGE MEASURED ON THE DIAMETER |

1.6/2.4 MM |

20°C 70°C |

≥55 KV/MM ≥45 KV/MM |

MECHANICAL CHARACTERISTICS

| TENSILE STRENGTH ON DELIVERY | σB | ≥20 N/mm2 | |

| TENSILE STRENGTH AFTER AGEING | 28d/80°C | ΔσB | ≤+10% |

| ELONGATION TO BREAKING POINT ON DELIVERY | εB | ≥150% | |

| ELONGATION TO BREAKING POINT AFTER AGEING |

28d/80°C SEC VDE0472/602 |

ΔσB | ≤+15% |

|

HEAT DISTORTION (REDUCTION OF THE WALL THICKNESS) |

SEC VDE0472/609 |

80°C/4h 70°C/4h |

≤40% ≤25% |

* The information contained in this bulletin is the result of accurate research and numerous laboratory experiments. However, considering the many practical applications, it is provided as an example only, and we decline any responsibility..

Single-pole rigid wires and cables with a trefoil structure coated in polyvinyl chloride (PVC) for windings on motors submerged in a bath of water.