UNOBOX soundproofed ROSENBERG®

- Quick easy installation thanks to the compete assembly of the components in the box.

- No special roof construction required, especially for sloping roofs.

- Air discharge from any side, by suitable positioning of the side panels.

- Built using double layer soundproofing panels with thermal insulation.

- Reduction of perceived noise level due to installation in the building.

- Very low formation of condensate, thanks to the aluminium, double chamber profile.

- Rotation speed 100% adjustable by varying the voltage or using the inverter of the external rotor motor used..

- Special variations to meet the client’s specifications, due to autonomous production of the motors.

- Simple installation of equipment, accessories, and regulators.

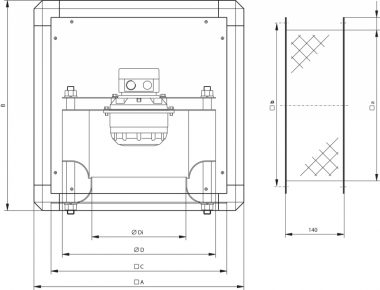

The Rosenberg UNOBOX fan boxes have a cubic frame made of aluminium sections and double layer panels to cover them. The ventilation units are of a backward blade type with the aluminium impeller keyed into the flange of the rotor of a motor with an external Rosenberg rotor. The UNOBOX equipment was conceived for the treatment and transport of medium and low flow rates between 800m3/h and 10.000m3/h. Typical fields of application are therefore the ventilation of apartments, shops, supermarkets, production units, bathrooms, canteens, warehouses and garages, i.e. in all the cases where slightly dirty air is to be extracted. On account of the installation in the building a special construction on the roof is therefore not necessary and nor is it necessary to occupy aeration holes in the roof itself. This leads to equally evident advantages in terms of noise reduction, especially in mixed urban zones. If compared to the solution with roof extractors, the sound pressure level is in fact decidedly lower thanks precisely to installation inside the building.

FRAME

- Loadbearing structure in double chamber aluminium profiles, and aluminium angle profiles.

- Panelling 20 mm thick, with the double layer of galvanised steel plating, insulated using flameproof glass wool, which provides soundproofing and insulation.

DIRECTION OF ROTATION

The standard direction of rotation in the fans is to the right (seen from the intake side). If it rotates in the incorrect direction (blade curved forward, for example) there is a serious risk of overloading the motor. The correct direction of rotation must therefore be checked at the time of starting up.