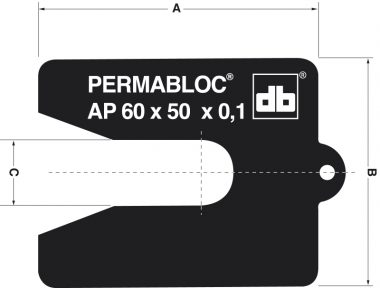

PERMABLOC ® Pre-cut spacers

- These are available in 4 different sizes, each with 8 different thicknesses, so as to provide the right correction in alignment for each machine;

- They are made of excellent quality stainless steel, to prevent corrosion when they are exposed to acids and alkalis;

- Markings concerning dimensions and thickness allow immediate identification;

- They are perfectly flat to ensure stability and consistent support for the machine over the entire support surface area;

- They are entirely deburred, with rounded corners, to reduce the risk of cuts during alignment operations;

- They have a perforated tab to facilitate positioning and removal;

- They are reusable.

WHY IS IT ECONOMICAL TO PURCHASE SPACERS?

A practical example:

Annual requirement of spacers

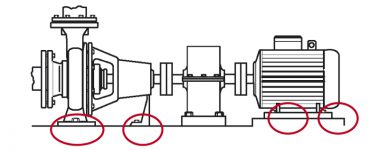

= Total number of machines x 4 feet/machine x 3 spacers/foot

= 100 machines x 4 feet/machine x 3 spacers/foot

= 1200 spacers consumed per 100 machines(*)

(*) Values referred to the average of 1 Alignment/year

Costs

Hourly cost per person = 20 Euro

Cost per minute per person = 0.38 Euro

Cost of 1 PERMABLOC model 0710055 0.7 mm spacer = 1.285 Euro

Time taken

Producing spacers for yourself involves a series of operations:

- Obtain the cutting instruments and raw material

- Cut the edges of the spacer

- Cut out the spacer

- Deburr

the average time taken to produce 4 spacers is about 30 min. (7.5 min. per spacer).

Considering that on average a machine is spaced with 2 or 3 spacers per foot we will have:

4 feet x 2.5 spacers/foot x 7.5 minutes/spacer = 75 minutes only to produce the spacers for one machine.

Economic comparison

Cost of producing 4 spacers size 0.7 mm 0.38 Euro x 30 min. = 11.4 Euro

Purchase cost of 4 PERMABLOC 0.7 mm spacers = 5.14 Euro

Conclusions

As you can see from the example the saving is 6.26 Euro for 4 spacers. Therefore, as suggested at the beginning, considering an average consumption of about 1200 spacers per year, for 100 machines the net saving is 1,878 Euro per year.

Furthermore, there are other benefits such as simplicity of use, the value of the spacer is always controlled, a large range of different sizes is available, there are no burrs and the quality of the stainless steel used is high.